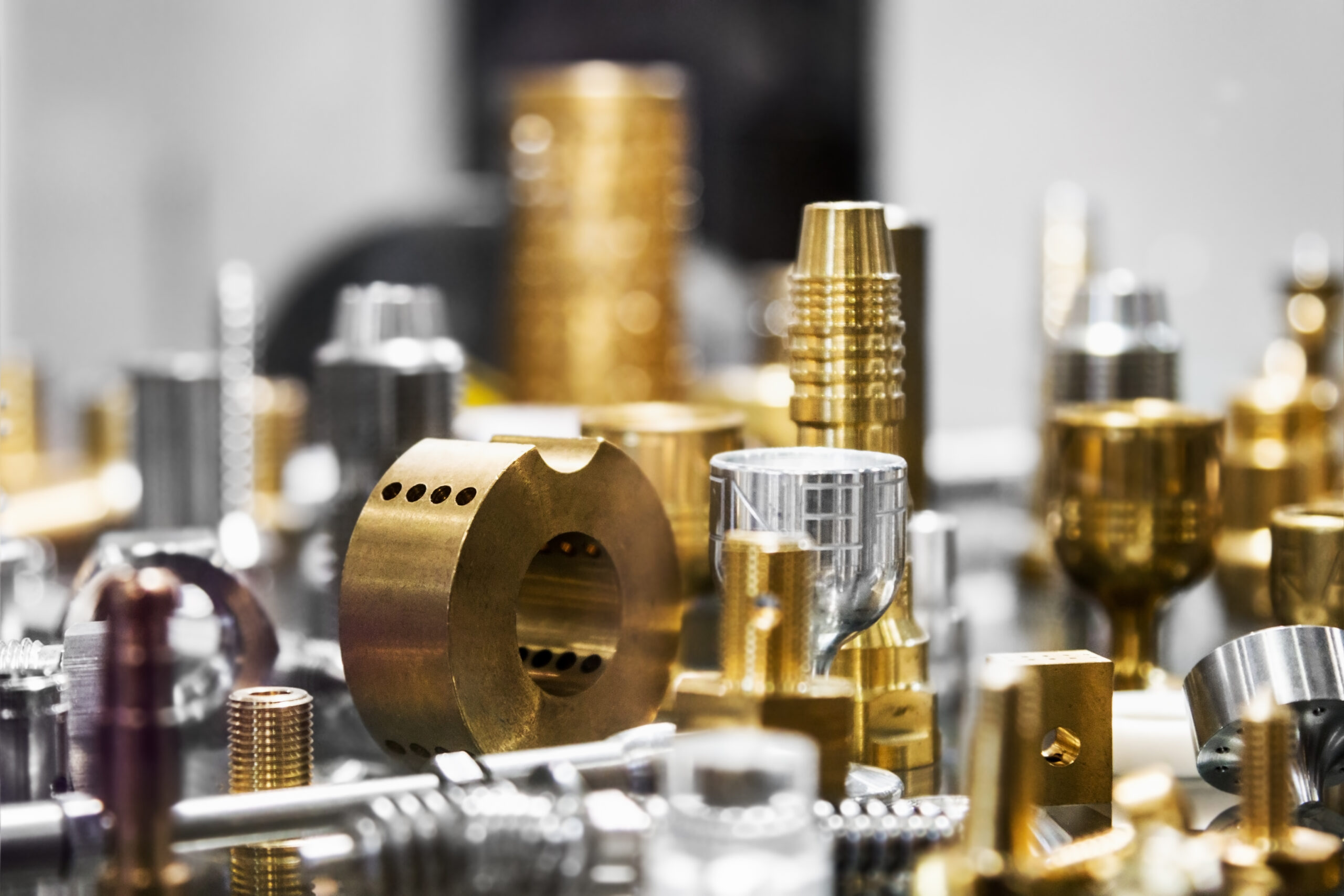

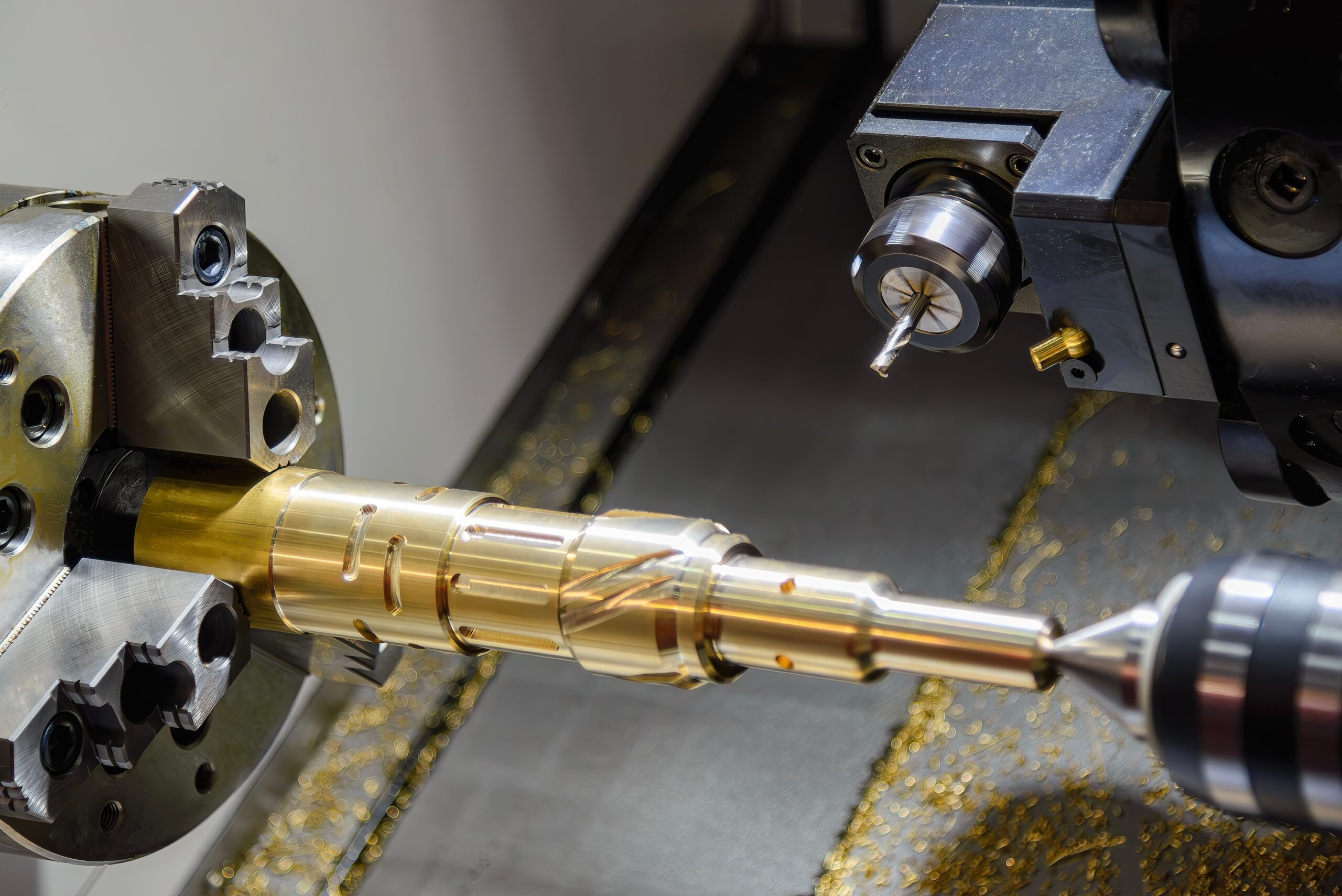

Dura Bronze Alloys achieve their outstanding mechanical performance through a synergy of carefully controlled composition, precisely managed microstructure, and balanced manufacturing processes extrusion, cold forming, and heat treatment. Next to their exceptional wear resistance and tribological performance, the Alloys even outperform standard aluminum and phosphor bronzes, while offering a less demanding alternative to many steels—striking an ideal balance between efficiency, cost, and quality.